US adds MEMS, sensors to military ordnance

Article By : Peter Clarke

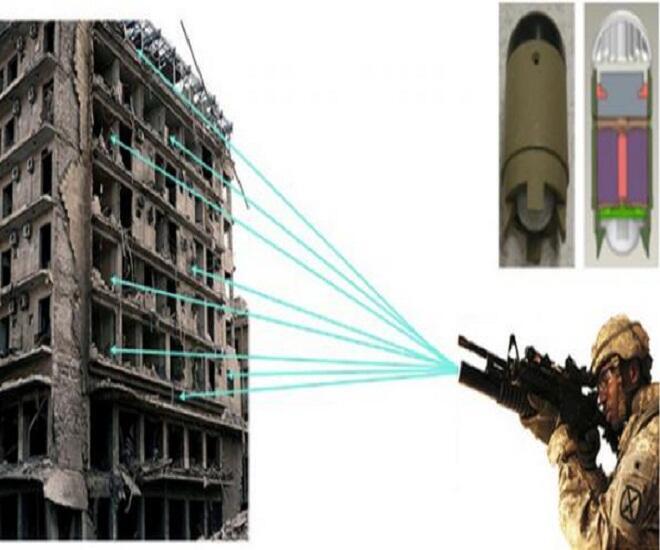

ARDEC has introduced a bullet equipped with wireless sensor nodes and uses MEMS as primer.

Several works have been made by the U.S. Army Armament Research, Development and Engineering Centre (ARDEC) based at Picatinny Arsenal, New Jersey. These include the Small Arms Deployable Sensor Network that allows intelligence gathering from inside a building without entering. ARDEC has developed wireless sensor nodes (WSNs) that fit into a small-arms round and be fired into a building. The WSN includes microphones, magnetometer, still image camera, GPS and a mesh radio network that is capable to sense and report the presence of the people in the building.

In addition to their work is the development of proximity sensors small enough to fit into 30mm calibre ammunition, guidance and control systems that fit into 40mm projectiles, miniature laser igniters for small calibre ammunition and small, high-density power sources.

Safe-and-arm devices make sure that projectile fuses only become armed and detonate under specific conditions and with modern electronics and those conditions can be increasingly complex using MEMS and electronics. Often the MEMS use metallic LIGA (Lithographie, Galvanoformung, and Abformung) for reasons of structural strength.

An artillery fuse is designed to arm only after experiencing the extreme acceleration of gun-launch and the intended spin rate and travelling a safe distance from the artillery gun crew. Precision munitions often have additional safety features in the fuse firing circuit to assure the projectile is properly guiding before becoming fully armed.

ARDEC is designing safe-and-arm devices based on MEMS and that require high voltages to detonate. These systems move away from traditional mechanical safe and arm devices that would use clockwork mechanisms to slowly rotate detonators to be in line with the rest of the firing train.

According to ARDEC, “it has successfully demonstrated MEMS fusing in 155mm and 40mm projectiles and is currently working on manufacturing technology for production transition.”

They also implement silicon-based MEMS technology for inertial measurement units for guided projectiles such as Excalibur. The U.S. Army is replacing larger devices based on air-bearing gyroscopes and ring-laser gyroscopes for the inertial guidance reference in precision munitions with silicon MEMS IMUs.

"We are using similar sensors to what you would find in game controllers or in your phone, just more reliable," said William Smith, the director of fuse and precision armaments, in a report. However, such IMUs need to be able to withstand accelerations up to 15,000Gs in gun-launch environment.

First published on EE Times Europe.