Market Interests Before Engineering Integrity

Article By : Junko Yoshida

What do spontaneously combusting hoverboards have in common with the catastrophic crashes of Boeing 737 Max airliners?

Compared to the recent catastrophic crashes of Boeing 737 Max airliners, the consumer hoverboards that “literally” caught fire in 2015 seem like small potatoes.

The scale of damage caused by system failures in either case is vastly different. And yet, both times, the elements under scrutiny are safety design principles and the verification process that responsible parties were supposed to follow.

Of course, an event as disastrous as an airplane crash demands detailed investigation both internally and externally. In Boeing’s case, the protracted fact-finding mission has involved many interviews and simulations, complicated by finger pointing and the inevitable claims of plausible deniability all around.

Finding the crux of the issue in a complex system is not easy, especially when the corporation involved is better at cover-ups up than transparency. Even harder is coming up with a clear-cut remedy, as business interests clash with goals that might not lead to any identifiable monetary return on investment.

In contrast, the case of the exploding hoverboards might be an easier place to start studying safety-critical design issues — by tracing causes and extracting the do’s and don’ts.

Global hoverboard crisis

First, let’s get back to why hoverboards became a global crisis.

First, hoverboards do not actually hover. A hoverboard is a glorified roller board powered by batteries. These toys became a must-have gift item for the holiday season in 2015.

Six months later, more than 500,000 hoverboards had been recalled because of the risk of fire or explosions. By mid-2016, the U.S. Consumer Product Safety Commission, announced: “There have been at least 99 incident reports of the battery packs in self-balancing scooters/hoverboards overheating, sparking, smoking, catching fire and/or exploding… including reports of burn injuries and property damage.”

Perfect storm

The hoverboard craze and the resulting consumer safety issues illustrate a perfect storm of market forces.

First, hoverboards occupied a whole new product category. As soon as the first hoverboards hit the market in 2015, product recognition among consumers soared, thanks to YouTube video clips featuring celebrities like Justin Bieber’s “Epic HoverBoard Dance Cover.”

Ken Boyce, principal engineer director, energy and power technologies at UL (previously known as Underwriters Laboratories), told us hoverboards “grabbed global attention, and manufacturers couldn’t produce them fast enough.”

That generated a potentially huge new market attracting a lot of new entrants, including many Asian manufacturers. All faced tremendous time-to-market pressure. “They all had to design it very quickly,” observed UL’s Boyce, often based on “tribal knowledge.”

In other words, everyone was making stuff up as they went along. Did any of these companies have internal safety engineering standards? No. They relied on “unwritten information that is not commonly known by others within a company.” That’s Boyce’s definition of “tribal knowledge.”

Last but hardly least, there was no “hoverboard industry” to speak of. Hence, no hoverboard safety standards with which suppliers could comply, even if they wanted to.

According to Boyce, “Faster product development, global supply chain, more startup companies and quicker consumer demands all presented serious challenges to…safety.” Indeed, many hoverboard vendors, with no experience dealing with lithium-ion battery hazards, just saw an immediate opportunity to rake in the dough. The potential hoverboard market looked too good to be true, and the pressure to manufacture as fast as possible was irresistible. Market demand was [an] ample excuse to cut corners in hopes of getting away with it.

Safety requirement standards ‘within weeks’

That was the moment UL stepped in.

Forget the complaints you often hear in Silicon Valley — that “standards take too long to develop.” In this instance, UL hammered out safety requirement spces for hoverboards “within a compressed period of several weeks,” Boyce said.

Already alarmed by hoverboard fire incidents, UL worked throughout the holiday season of 2015 on safety analyses and technology research. Boyce’s team also recorded incidents and wrote a safety requirement standard. UL published its results as UL 2272 before the end of January 2016. Five months after Boyce’s team started to investigate hoverboard safety, UL was able to roll out the hoverboard safety certification program. By the end of 2016, UL issued a “consensus” regional standard for hoverboard safety in the United States and Canada.

“Consensus” standards vary from other big standards like those by ISO. They are developed through the cooperation of all parties with an interest in participating in development and/or use of the standards. Consensus requires consideration of all views and objections, and an effort toward resolution. The hoverboard safety standard is an example of how nimbly and quickly an independent organization like UL can resolve a safety crisis for a consumer product.

Thermal runaway

While a product catching fire seems like a simple, straightforward accident, the hoverboard is actually “a complex system,” as Boyce explained.

E-bikes, e-scooters, power tools and electric vehicles like Tesla have all experienced thermal runaway because they use lithium-ion batteries as an energy storage medium. These battery packs consist of several battery cells and a battery management system.

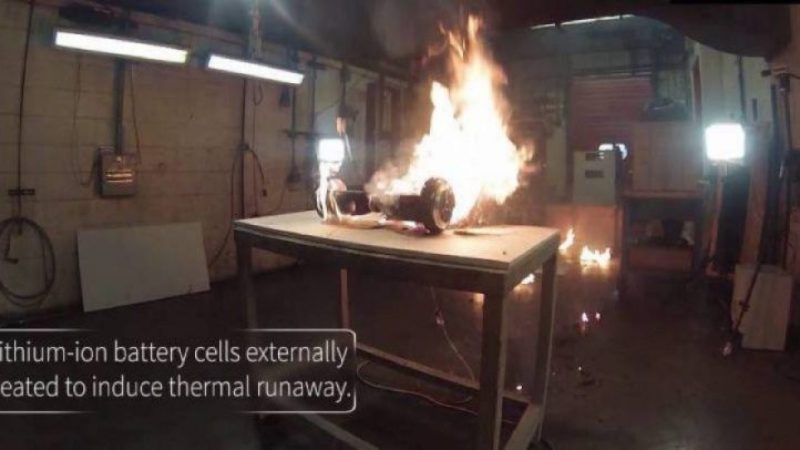

When one cell in a lithium-ion battery goes into thermal runaway, the “virus” can spread in a domino effect to other cells, ultimately damaging the entire battery powering a hoverboard. It amounts to an unstoppable chain reaction.

Two authors at Rutoronik Elektronische Bauelemente GmbH — Andreas Mangler, director, strategic marketing and communications, and Roland Hofmann, product sales manager, thermal management — described thermal runaway as follows:

The temperature rises rapidly within milliseconds and the energy stored in the battery is suddenly released. Temperatures of around 400°C are thus created, the battery becomes gaseous, and a fire erupts that can hardly be extinguished by conventional means. The risk of thermal runaway begins at a temperature of 60°C and becomes extremely critical at 100°C. When the battery actually catches fire depends on the specific cause.

This threat underscores the importance of a battery management system. It’s there to ensure that the battery remains in its specified working range. This requires very precise measurement of charge and discharge currents, cell voltage, and temperature.

It’s important to note that lithium-ion batteries have a narrow operating temperature range of between +15 and +45°C. The functional safety, service life, and cycle stability of the battery cell — thus the functional safety of the battery and the entire electric car or electric tool system — depend largely on the cell staying within this range.

If the temperature exceeds a critical level, thermal runaway occurs.

Thermal runaway has several triggers – including an internal short circuit. For instance, if a hoverboard falls from a great height, the battery is deformed, material penetrates the battery cell and incites an internal short circuit. Other causes are external short circuits (deformation of the battery cell), overcharging the battery, and excessive currents when charging or discharging the battery.

Noting that many hoverboard fire incidents required an emergency response, the UL FSRI (Fire Safety Research Institute) created this video to let the firefighters know what they were up against:

Third-party certification

In ensuring aircraft safety, the Federal Aviation Administration (FAA) plays a key third-party role in assessing safety.

However, the recent Boeing 737 Max crashes exposed the reality that even the FAA, an agency revered as the global standard for upholding aircraft safety, was less than independent from the manufacturer in the process of testing and assessing safety in new aircraft.

Worse, however, is the U.S. automotive industry. Carmakers are notorious for insisting on their independence from federal agencies. They have in most cases self-certified the safety of their vehicles.

With the advent of autonomous vehicles and integration with complex embedded software, it remains to be seen if carmakers will decide to seek help from third-party testers/assessors to ensure AV safety.

In the hoverboard crisis, UL demonstrated its unmatched ability to seize leadership not only developing a safety standard, but also testing and certifying it. UL 2272 covers the electric drive train including the rechargeable battery and charger system combination in self-balancing scooters.

Discussing the role of third-party assessors in ensuring product safety, Boyce cited a consumer product market survey done by the Testing, Inspection and Certification (TIC) Federations last year.

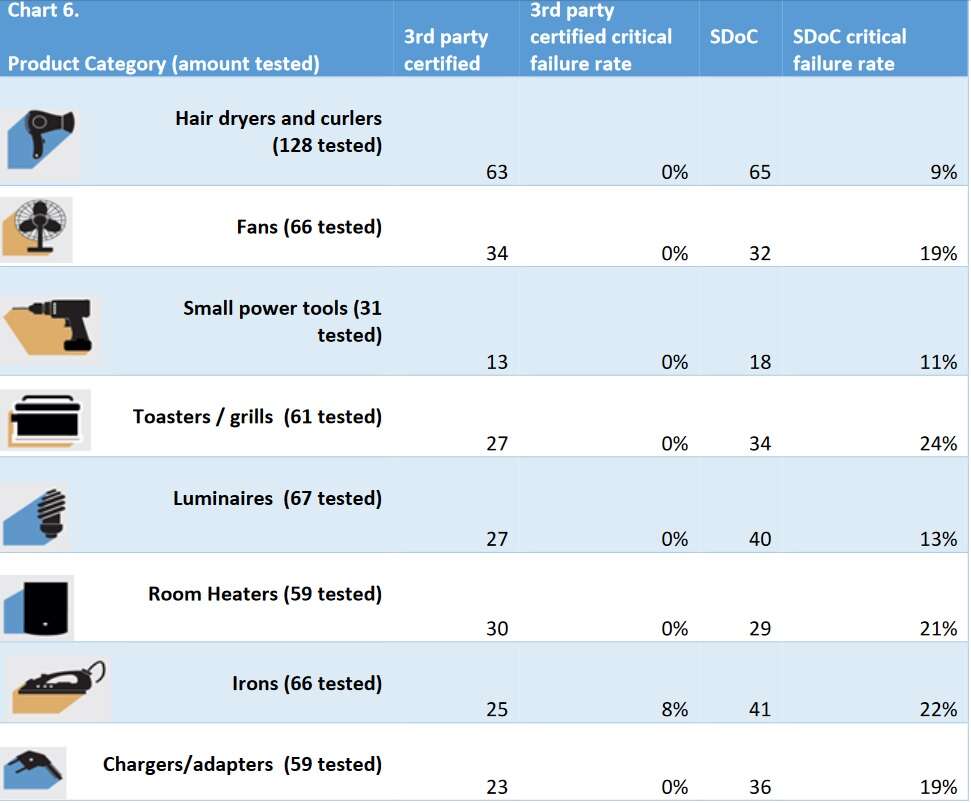

The market survey compared the compliance rate in certain categories of consumer products available in North America and Europe that were assessed by: (1) a first-party evaluation (commonly referred to as Supplier’s Declaration of Conformity (SDoC)) and (2) an independent third-party conformity assessment body (CAB).

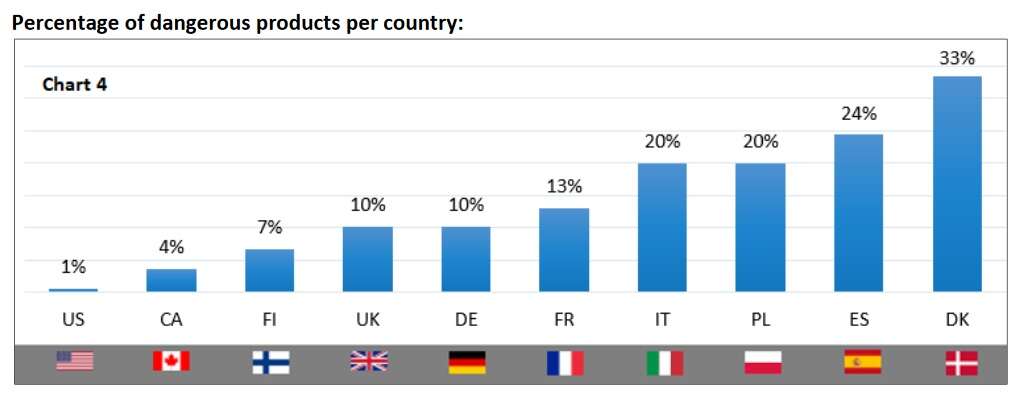

TIC purchased 537 random samples from retailers throughout North America and Europe. The survey revealed that approximately 10 percent of the products sourced in EU were certified by an independent third-party, whereas those purchased in North America were certified 95 percent of the time. The discrepancy appears to stem from different regulatory approaches in different countries.

Ultimately, the survey results showed that of all products tested, 17 percent of self-declared “safe” products showed dangerous faults, compared to less than 1 percent of such faults in products that were certified by an independent third party.

(Source: TIC Federations Consumer Product Market Survey)

The chart above shows a breakdown by country. Countries that rely on a third-party model presented the lowest rates of dangerous faults. Conversely, countries that rely on a Supplier’s Declaration of Conformity presented higher danger rates.

(Source: TIC Federations Consumer Product Market Survey)

Products surveyed that were third-party certified presented zero critical failures, with the exception of electric irons — which demonstrated two critical failures.