IBM discovers how to convert old smartphones cases into high-strength plastic

Article By : Vivek Nanda

The one-step approach converts BPA-leaching plastics in consumer electronics into environmentally safe material for water purification and medical devices.

Scientists at IBM Research's Almaden lab, San Jose, have discovered a one-step chemical process that converts polycarbonates into plastics that can be used for fibre optics and are safe enough even for use in water purification and medical equipment.

IBM Researchers added a fluoride reactant, a base, and heat to old CDs to produce a new plastic with temperature and chemical resistance superior to the original substance. When the powder is reconstructed into new forms, its strength prevents the decomposition process that causes BPA leaching.

You would recall BPA from its use in polycarbonates that decompose and leach the chemical, which, if ingested, can affect the brain. BPA has been replaced by the bigger brands with other chemicals, the impact of which is unknown.

![[Jeanette Garcia and Gavin Jones]](/wp-content/uploads/sites/4/2020/04/JeanetteGarcia_GavinJones_IBMResearch_NewPlasticFromOldCDs.jpg)

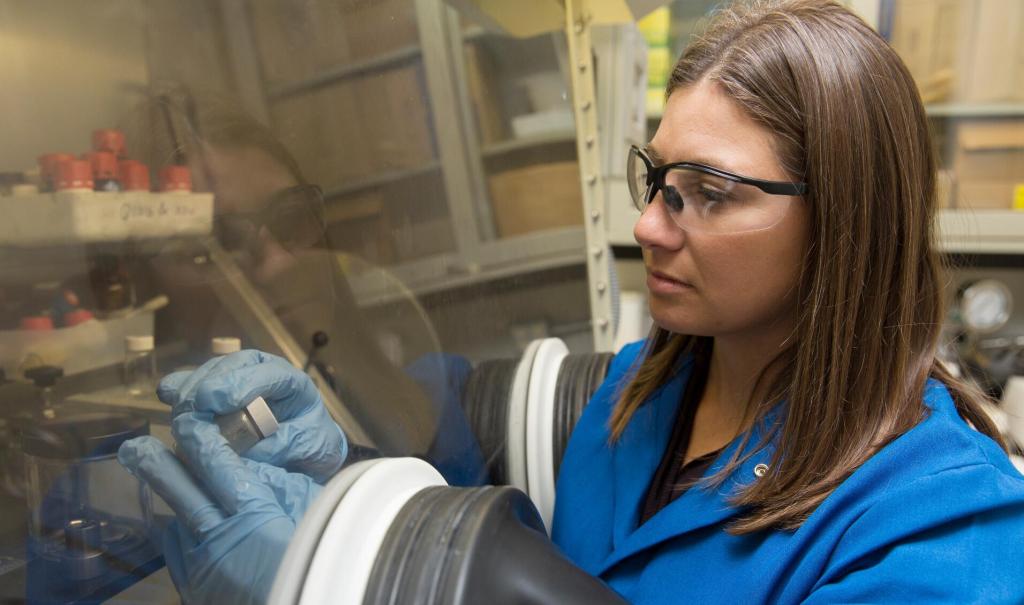

Jeanette Garcia and Gavin Jones, research staff, IBM Research, Almaden lab. Their use of predictive modeling and experimental lab work to make the discovery will help advance cognitive systems that aid in materials discovery.

"Polycarbonates are common plastics in our society—especially in consumer electronics in the form of LED screens, smartphones and Blu-ray discs, as well as everyday eyeglass lenses, kitchen utensils and household storage gear," said Gavin O. Jones, Ph.D., research staff member. "We now have a new way of recycling to improve how this prominent substance impacts the world's health and environment."

"While preventing these plastics from entering landfills, we simultaneously recycle the substance into a new type of plastic—safe and strong enough for purifying our water and producing medical equipment," said Jeanette Garcia, Ph. D., research staff member.

This is particularly good news for the participants in April at the ISRI workshop on measuring and maximising the business and environmental benefits of plastics recycling. It is estimated that every year, we generate over 2.7 million tonnes of a plastic—polycarbonate—to create common household items, such as CDs, baby bottles, eyeglass lenses and, yes, all sorts of consumer electronics applications.

Preductive modelling aids discovery

A combination of predictive modelling and experimental lab work helped Jones and Garcia make the discovery. They will take lessons from the research efforts to advance cognitive systems that help accelerate the materials discovery process. IBM's Watson Discovery Advisor is one such system.

IBM Research has been actively looking for solutions to reduce pollution from technology. Last year, their China operations launched Green Horizons, a Watson-like system to forecast energy usage in cities to help better integrate renewable energy sources.